headset bearings

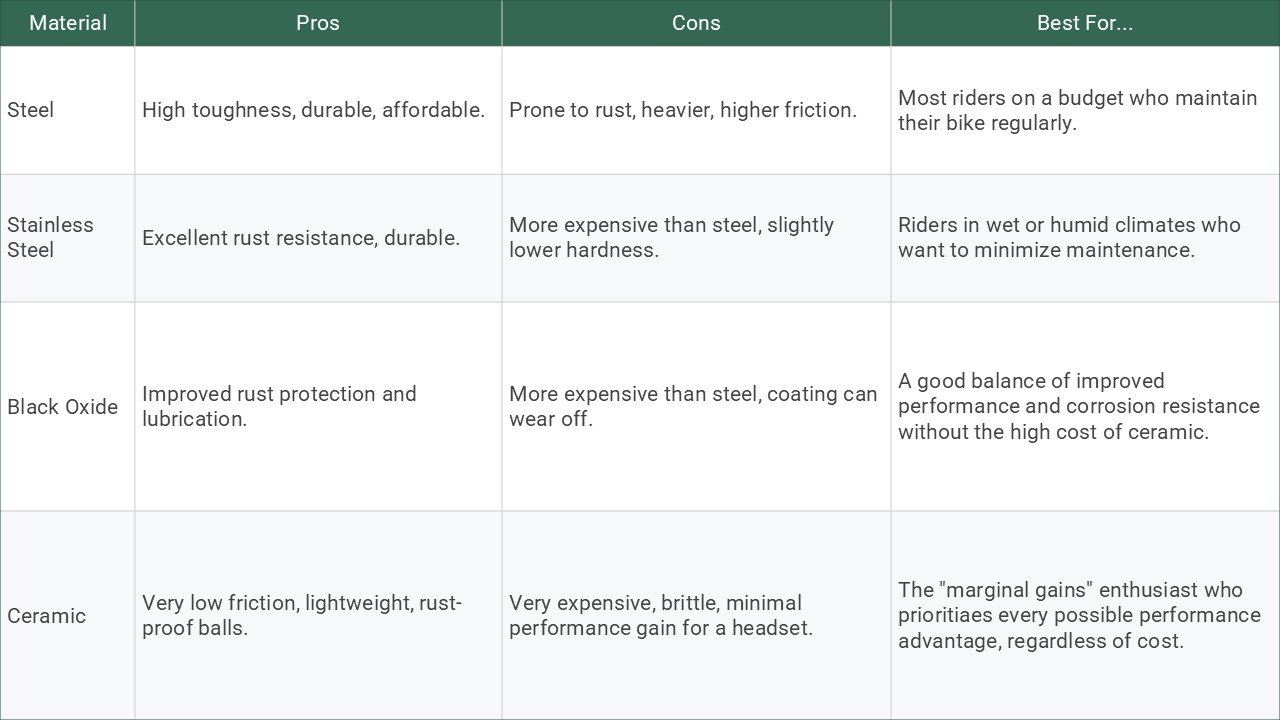

Which is the best bearing material for a headset bearing? — steel, stainless steel, black oxide, and ceramic—each has its own set of advantages and disadvantages. The best choice depends on your priorities: cost, durability, weight, and resistance to environmental factors.

Here's a breakdown of the key characteristics of each:

1. Steel (Chrome Steel / Carbon Steel)

This is the most common and traditional material for bicycle bearings.

Advantages:

Cost-Effective: Steel bearings are significantly less expensive than other options, making them the standard for most bikes.

High Toughness and Load-Bearing: Steel is very strong and can withstand high impact loads and radial forces without chipping or cracking, which is ideal for a component like a headset that handles the force from bumps and potholes.

Durability: With proper maintenance (regular cleaning and lubrication), a good quality steel bearing can last for a very long time.

Disadvantages:

Susceptibility to Rust: Steel is prone to corrosion when exposed to moisture, especially from rain, sweat, and washing your bike. If not properly sealed and greased, they will rust and become pitted, leading to a gritty feel and premature failure.

Weight: Steel is heavier than ceramic, which adds a small amount of weight to the bike.

Higher Friction: Steel-on-steel contact has a higher coefficient of friction than ceramic, which can lead to slightly more rolling resistance. While this is negligible for a headset bearing (which doesn't rotate continuously), it's a factor to consider for other components like hubs and bottom brackets.

2. Stainless Steel

Stainless steel bearings are a step up from traditional steel, primarily in their resistance to rust.

Advantages:

Corrosion Resistance: The main benefit of stainless steel is its excellent resistance to rust and corrosion. This makes it a great choice for riders who frequently ride in wet conditions, wash their bikes often, or live in humid environments.

Good Durability: Stainless steel bearings are still very durable and can handle the loads of a headset.

Reduced Maintenance: Due to their resistance to rust, they require less frequent maintenance and cleaning to prevent corrosion.

Disadvantages:

Higher Cost: Stainless steel bearings are more expensive than standard steel.

Lower Hardness: Some grades of stainless steel (like 440C, a common bearing material) are not as hard as high-carbon chrome steel. While still plenty durable for a headset, they may not have the same ultimate load-bearing capacity.

3. Black Oxide

Black oxide is a coating applied to the steel bearing races and balls. It's not a different material for the bearing itself but a surface treatment.

Advantages:

Corrosion Resistance: The black oxide coating adds a layer of protection against rust and corrosion. While not as effective as stainless steel in extreme, constant moisture, it provides a significant improvement over uncoated steel.

Improved Lubrication: The porous nature of the black oxide layer helps the bearing retain lubricant on its surface, which can lead to better lubrication conditions, especially during the break-in period and at startup.

Reduced Friction/Wear: The coating helps to reduce wear and "smearing" (adhesive wear from sliding friction) between the balls and races. This can lead to a smoother, longer-lasting bearing.

Disadvantages:

Not a Cure-All: Black oxide is a coating, not the base material. If the coating wears away or is compromised, the underlying steel is still susceptible to rust.

Cost: Black oxide bearings are typically more expensive than standard steel bearings.

4. Ceramic

In the context of bicycles, "ceramic bearings" usually refers to hybrid ceramic bearings, which have ceramic balls (usually silicon nitride, Si3N4) in steel or stainless steel races. Full ceramic bearings (with ceramic races) are very rare and not recommended for bicycles.

Advantages:

Corrosion Resistance: Ceramic balls are highly resistant to corrosion and rust.

Lower Friction & Rolling Resistance: Ceramic balls are smoother, harder, and rounder than steel balls, which significantly reduces friction. While this is a major selling point for continuously rotating components like bottom brackets and hubs, the effect on a headset bearing (which only turns when you steer) is negligible for most riders.

Lighter Weight: Ceramic balls are lighter than steel, contributing to a small weight savings.

Longevity: Ceramic balls are much harder than steel, meaning they are more wear-resistant. In theory, this can lead to a longer lifespan.

Disadvantages:

High Cost: Ceramic bearings are by far the most expensive option. For a headset, the performance benefits are minimal for the significant price increase.

Brittleness: While extremely hard, ceramic is more brittle than steel. This makes the balls susceptible to chipping or cracking under high-impact loads, such as hitting a pothole. While this is more of a concern for hubs, it is still a consideration.

Risk of Pitting: Because the ceramic balls are so much harder than the steel races, if contaminants like dirt or grit get into the bearing, the ceramic balls can "pit" or dent the softer steel races, leading to a rough, gritty feeling.